Phone: +31 (0)85 058 0046

E-mail: infoaanvraag@dynaflow.com

E-mail: infoaanvraag@dynaflow.com

ABOUT US

HEAD OFFICE

Laan van Oversteen 20

6th floor

2289 CX Rijswijk

The Netherlands

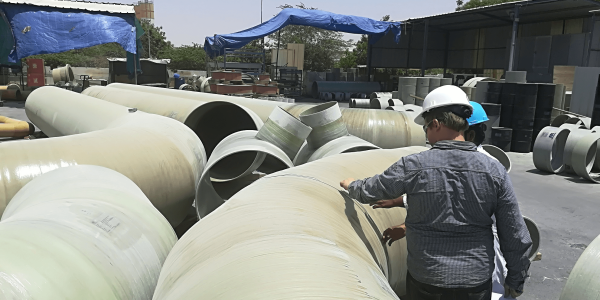

The design, manufacturing, qualification, and installation of FRP piping systems differs considerably from that of more traditional materials due to the anisotropic nature of FRP. Fiber Reinforced Plastics (FRP) piping has been used in the industry since the early sixties. The last decades have shown a large growth in the use of FRP.

From the onset of the application of FRP systems, DRG has been involved in the development and introduction of FRP for pressurized applications. Since our founding in 1989, DRG has developed a unique service portfolio dedicated to the design of piping systems including fiberglass systems. DRG is also a founding member of the ISO14692 committee, and the DNV Committee for certification of fiberglass craftsmanship, and is (co-)author of many technical papers and code contributions.

Because of our active involvement in ISO, DNV, and NEN committees from the early start of the application of FRP, our knowledge and understanding are always up to date and meet the most recent international standards. This makes our services unique worldwide and has provided DRG with a leading role as an engineering company specializing in FRP applications.

We provide engineering services at all stages of the project life-cycle, from initial feasibility studies and conceptual design during the FEED stage, followed by system design, material specification, and qualification up to engineering support during installation. Major end-users like Shell, BP, BASF, and many more use our services when dealing with FRP piping for systems like cooling water. We are acknowledged as a reliable and independent consultant with a practical approach to fiberglass engineering solutions.

The inclusion of Fiberglass Reinforced Plastic (FRP) knowledge and experience from the very early stage of a project will avoid costly delays and other unforeseen costs that may arise at a later stage in the project.

The large variety of glass reinforcement types, resin types, and thermoplastic liners, requires the material selection to be tailored to the specific application of the fiberglass system.

There are a number of critical aspects to consider once the vendor for the fiberglass piping components is selected in order to assure a good quality system.

Studies have shown that most failures of Fiber Reinforced Plastic (FRP) systems are the result of poor design, poor qualification, and construction errors. On-site inspections are crucial to avoid expensive system failures.

Fiberglass failures may occur during the construction phase, during the commissioning phase (hydro-testing), or operation. Independent of the event, what you want is a quick solution to repair your pipe system.

DRG applies its in-depth knowledge of the fiberglass laminate material to assist manufacturers in the development of new pipe wall architectures, fittings, or other pressure-holding components.

Most of the codes and standards related to Fiberglass Reinforced Plastic (FRP) are performance-based and require verification of the specified qualified pressure of each component.

Laan van Oversteen 20

6th floor

2289 CX Rijswijk

The Netherlands

© Dynaflow Research Group BV