Consulting Services

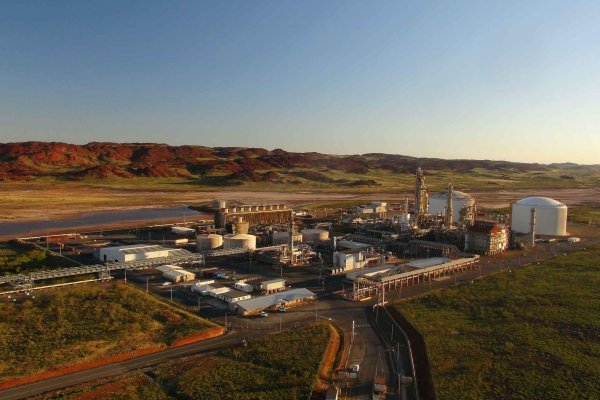

Dynaflow Research Group provides specialized consulting services across a wide range of engineering disciplines, with expertise spanning from asset integrity management to fiberglass engineering.

In Asset Integrity, we specialize in the design, maintenance, and optimization of critical systems for process industries, prioritizing operational safety and environmental protection. Backed by over 35 years of global experience, our team offers expert guidance throughout the engineering lifecycle—from initial design to ongoing maintenance. We also conduct comprehensive on-site inspections worldwide, ensuring systems operate efficiently and safely.

Beyond asset integrity, our services emphasize the reliability and safety of industrial plants, offering customized engineering solutions such as cost-effective piping system designs and detailed dynamic system analyses to mitigate potential risks and improve performance.

Our expertise further extends to Fiberglass Engineering, where we are leaders in FRP piping system design and implementation. Additionally, in Equipment Engineering, we focus on verifying designs, addressing technical challenges, and delivering solutions that enhance both reliability and safety across industries.

With Dynaflow Research Group, you gain access to a team of trusted experts committed to solving complex engineering challenges and delivering innovative, practical solutions tailored to your needs.

Key Services

Key Services Dynaflow Research Group Provides

Asset Integrity

With a strong foundation of over 35 years of expertise, our Asset Integrity services are designed to ensure the reliability, safety, and longevity of critical systems in process industries. From the Front-End Engineering Design (FEED) stage to ongoing maintenance and compliance activities, we provide holistic engineering support tailored to meet client needs. Our specialized services include vibration measurements to identify operational risks, Barcol hardness testing for FRP equipment compliance, and digital monitoring solutions like REX equipment to optimize asset performance. By integrating advanced technologies and field expertise, we help clients maintain operational excellence and system integrity.

Plant Design

At Dynaflow Research Group, we understand the critical importance of Front-End Engineering Design (FEED) in achieving safe, reliable, and durable industrial plant and pipeline systems. With decades of experience, we deliver customized engineering solutions across industries such as petrochemicals, water, and renewable energy. Our services include cost-efficient piping system designs and flexibility analyses using advanced tools like Caesar II to optimize routing, support locations, and system functionality. Whether addressing a complex pipeline network or enhancing plant infrastructure, we provide innovative, safe, and cost-effective designs tailored to meet the diverse demands of modern industries.

Fiberglass Engineering

Dynaflow Research Group is a leader in Fiber Reinforced Plastics (FRP) engineering, specializing in the design, qualification, manufacturing, and installation of FRP piping systems for a variety of industrial applications. Since our founding in 1989, we have been instrumental in pioneering FRP solutions for pressurized environments and remain an active contributor to global standards as a founding member of ISO14692 and DNV committees. Our services include feasibility studies, conceptual design, material specification, qualification, and installation support, ensuring compliance with the latest international standards. Trusted by industry leaders like Shell, BP, and BASF, we deliver independent and reliable consultancy, offering resilient engineering solutions tailored to meet the challenges of demanding industrial environments.

Equipment

Our Equipment Engineering services focus on ensuring the safe, efficient, and reliable performance of industrial equipment across various sectors. By applying expertise in international design codes like ASME VIII and EN13445, we provide design validation, optimization, and troubleshooting services to meet the highest standards of safety and reliability. Whether improving the efficiency of heat exchangers or refining impeller designs for mixers, our engineers combine advanced simulation tools with deep technical knowledge to deliver effective and innovative solutions. Additionally, we offer validation and compliance checks, ensuring equipment meets industry standards such as ASME B&PV Code. With a proven history of solving complex challenges, we are a reliable partner for comprehensive equipment solutions tailored to your needs.