What is Hogging and Sagging and what are the effects on piping?

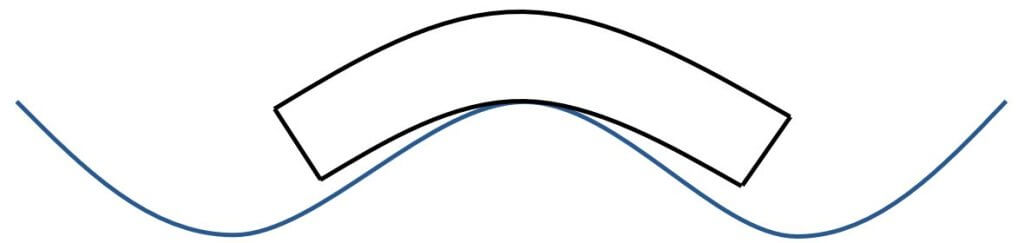

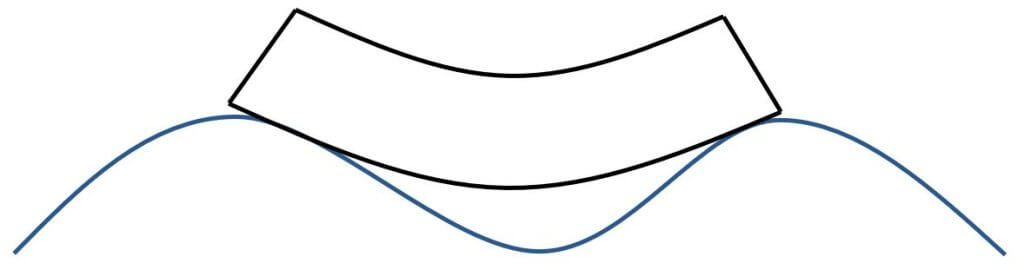

When waves pass over the length of a ship, the ships profile rises and bows following the peaks and troughs of said wave due to the changes in bouyancy along the length. This effect is known as hogging and sagging, the distinction being whether the ships centre is bowing upwards or downwards respectively.

The ship is not alone in the experiencing of this phenomenon, anything anchored to the ship is also in turn subjected to the displacements induced by hogging and sagging and thus experience bending moments. This includes ship piping, especially piping running lengthways down the ship.

How is Hogging and Sagging incorporated in our analyses?

DRG incorporates the effects of hogging and sagging by modelling the peak displacements induced by the phenomenon on the pipe supporting. Attention is payed to both the longitudinal coordinates of the support and the deck said support is attached to and the displacements calculated accordingly for both a hogging and sagging case. With these calculated displacments applied accordingly over the piping system, we encapsulate the hogging/sagging effects accordingly.

How can DRG help mitigate the effects of hogging and sagging on ship piping?

DRG has provided several solutions & recommendations to help mitigate the effects of hogging and sagging on piping these include:

- Piping reroutes & support layout, providing more flexibility for the piping

- Change of support steel structure to attach the support to a different deck, reducing the displacement differential between supports

- Modelling and confirming more realistic displacement scenarios (i.e., separation of 1- and 100-year storm and whether the piping will be under operation)