The project focused on evaluating the mechanical integrity and support strategy of a glass-reinforced plastic (FRP) piping system lined with unplasticized polyvinyl chloride (PVC-U), designed to protect the glass-reinforced plastic structural layer against the corrosive gas mixture. The temporary installation provides an additional gas cleaning stage for the sulphuric acid plant, connecting six filter silos and a centrifugal fan, and interfacing with a previously assessed double block-and-bleed (DBB) spool.

The stress analysis is performed according to ISO 14692-2005 standards. Special attention was given to the anisotropic properties of the FRP PVC-U piping.

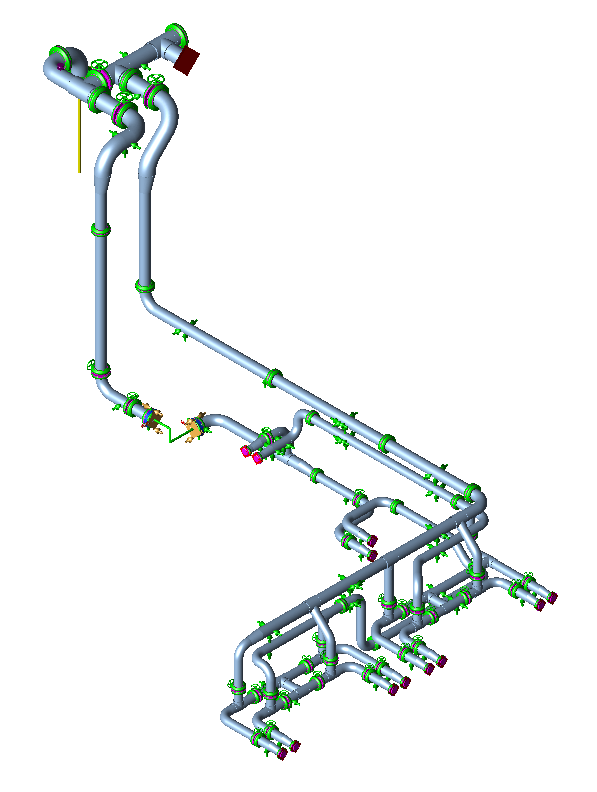

System Description and Modelling Approach

The system under review comprised multiple FRP PVC-U piping runs, with diameters ranging from DN600 at the DBB spool section to DN250 at the filter silo connections. The FRP layer, manufactured by Plasticon Composites, provides the structural strength, while a 5 mm red PVC-U liner offers corrosion resistance. Due to the liner’s low modulus of elasticity, only its weight is taken into account in the analysis.

Design and operating conditions were carefully defined, accounting for a corrosive gas mixture with a density of 1.124 kg/m³, a maximum system temperature, and a pressure rating aligned with the pipe class (PN16 for straight pipes, PN10 for fittings). The model was developed using Caesar II v.12, with geometry, loads, and boundary conditions derived from as-built isometrics, P&IDs, and client specifications.

Nine differential temperature cases were modelled to simulate non-uniform operational scenarios where branches are isolated and subject to differing thermal expansions. Wind loads were calculated per EN 1991 Eurocode 1, considering the system’s elevation profile and local terrain, with a maximum system height of 12.5 meters.

Piping and Component Specification

The structural FRP layer is a composite of filament winding, chopped strand mats, and woven roving. It has a glass content of approximately 60%. Mechanical properties were sourced from both manufacturer data and an internal database, with allowable stresses determined from long-term properties.

All flanged connections used stub ends with lapped FRP flanges. As per the client’s request, steel flange weights per ASME B16.5 were used. The flange analysis was based on the equivalent pressure method.

Load Cases and Analysis Methodology

A series of load cases were investigated. The most critical operating scenario (L3: Max Design operating) was identified, with additional cases considering support lift-off due to thermal expansion and high rigidity in specific sections. The DBB spool, previously assessed in a separate report, was subjected to further scrutiny to account for the influence of line continuations and wind-induced riser loads.

Nozzle loads for the mist filter were evaluated through finite element analyses (FEA). The effective allowables were based on strain and shear stress criteria per EN 13121-3-2004 and vendor data. For the fan connections, expansion joints with tie-rods were specified, but the calculated nozzle loads must be verified with the manufacturer due to the absence of allowables.

Key Results

Stress Distribution and system Integrity

Across all sustained load cases, system stresses remained well within allowable limits. The maximum observed stress was 55.1% of the allowable for the maximum design operating load case. Wind loads produced only minor increases in stress at the highest system elevations and were not a significant factor in overall safety margins. The DBB spool section showed a maximum stress of 29.4% under wind loading, a negligible increase over the baseline.

Support Layout and Restraint Loads

The original client-specified support layout proved sufficient for restraining the system and preventing excessive local stresses. However, several modifications were necessary near the DBB spool and fan nozzles to avoid exceeding nozzle allowables. Notably, a spring support at was relocated and resized, and additional guides/restraints were added.

Nozzle and Flange Loads

Mist filter nozzle loads remained within the allowable limits with the support modifications. Fan nozzle loads were minimized by the specified expansion joints, but must be verified by the manufacturer. Flange loads were within allowable limits system-wide, with the highest (72.5% of allowable) occurring at filter silo inlets due to conservative modelling of flexible tubing as rigid anchors. Real-world flange loads are expected to be substantially lower once actual tubing flexibility is considered. The highest non-anchored flange load was 57.6%.

Conclusions and Engineering Recommendations

The stress analysis confirms that the FRP PVC-U piping system for the gas filter installation is mechanically sound under all considered operating and environmental scenarios, provided that recommended support modifications are implemented. Flange and nozzle loads remain within conservative allowable limits, with stress concentrations well below code-based thresholds. However, the following actions are necessary for successful system deployment:

- Evaluate and reinforce supports at the DBB spool section as necessary, based on reported restraint loads.

- Communicate calculated fan nozzle loads to the manufacturer for approval, ensuring the selected expansion joints are compatible with equipment limits.

This project demonstrates the value of integrated modelling, conservative assumptions, and iterative support design in achieving safe, reliable, and code-compliant FRP piping installations in corrosive industrial applications.