Why Pay Attention to a Line Filling Process?

During a start-up/line filling process a wave front of fluid progresses it’s way through the empty* parts of the line. However, when this front is required to change direction through bends the change in momentum generates an unbalanced force, this unbalanced force is maintained until the wave front reaches another change in direction that counteracts the aforementioned force. The moving wave front and it’s corresponding forces can cause unwanted dynamic effects within a piping system.

How does DRG Analyse these Dynamic Effects?

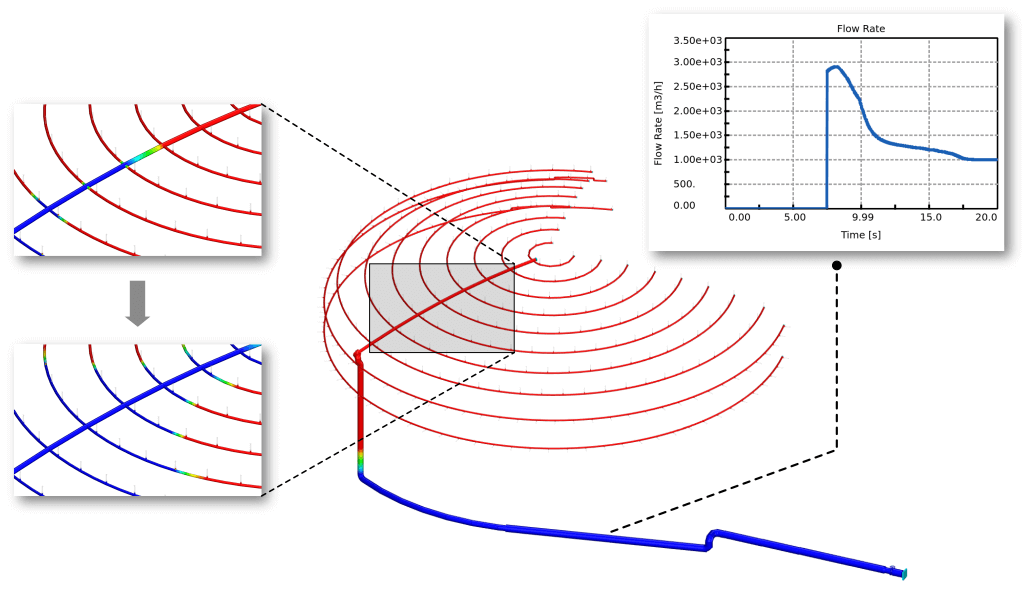

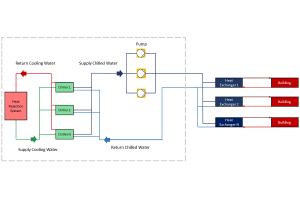

DRG first analyses the timings and impact forces that occur during the line filling, this is done using DRG’s inhouse software BOSfluids. Afterwards a time history analysis is performed in the stress analysis package CAESAR II. The resultant stresses are evaluated against the relevant piping codes.

What can be done to mitigate the Effects of Line Filling?

Various solutions can be developed to aid in safe line filling procedures, the majority of which focus on reducing the wave front velocities:

- Change valve opening times to desync dynamic effects and slow initial wave front velocities

- Introduction of Orifices/Flow Control Valves to reduce wave front velocities

- Change of support layout to mitigate dynamic effects