Stress Analysis and Remediation of Tank Lines

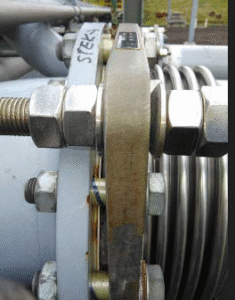

This case study presents the findings of a comprehensive pipe stress analysis of several tank lines following a leakage incident at an expansion joint. The

This case study presents the findings of a comprehensive pipe stress analysis of several tank lines following a leakage incident at an expansion joint. The

The project focused on evaluating the mechanical integrity and support strategy of a glass-reinforced plastic (FRP) piping system lined with unplasticized polyvinyl chloride (PVC-U), designed

This case study presents a technical assessment of the Glass Reinforced Plastic (GRP) piping system installation at a power plant, based on a visit conducted

The client experienced multiple unexpected failures in the underground firewater (FW) network at one of their facilities. The network utilizes fiberglass-reinforced plastic (FRP) piping. To

A heat exchanger was found to have fluid leakage from the tube side into the shell side after approximately 3 years of operation. Initial inspections

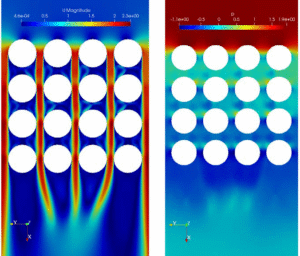

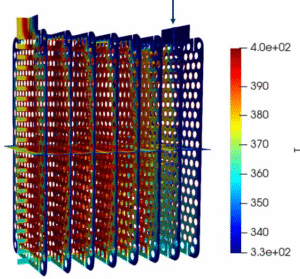

This project presents a detailed technical assessment of two vertical tube cooker (shell-and-tube heat exchanger) designs using Computational Fluid Dynamics (CFD). The analysis was conducted

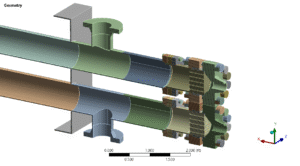

Dynaflow Research Group was asked to conduct a comprehensive finite element (FE) analysis on a custom hairpin heat exchanger. The primary objective was to assess

Effective mixing in bioreactors is essential for maximizing mass transfer, homogenizing chemical species, and ensuring uniform biological activity. The client undertook a computational fluid dynamics

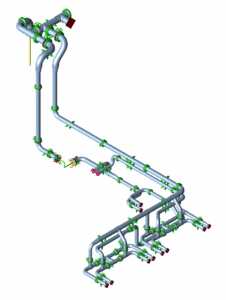

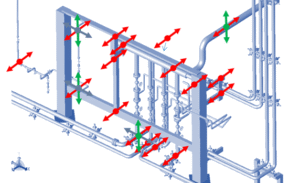

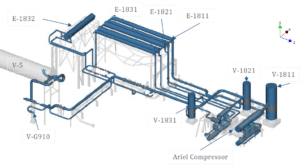

Excessive vibrations were detected in the discharge piping of compressor C801 at BP Rotterdam. The observed vibration frequencies corresponded to the compressor’s running speed and

The API 618 DA3 study at the Q8 Terminal, commissioned by Wintershall Noordzee and executed by Dynaflow Research Group, was initiated to ensure the mechanical