Feasibility Study

Introduction

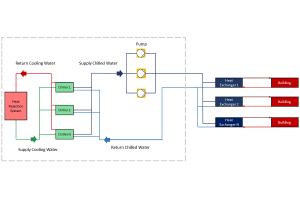

A cooling water system consists of a large underground branched GRP piping system connecting to steel branch continuations at each U/G-A/G interface. In the detailed design phase the fitness for purpose of the GRP part of the system will be demonstrated by the GRP supplier by means of a surge and stress analysis. In order to avoid/anticipate unexpected problems during the detailed design of the GRP part, a number of feasibility assessments have been made.

Analysis

Based on preliminary analysis the design pressure for the selected GRP header system was selected at 10 barg. The combination of the 10 barg internal design pressure and the large size (NB 2700 mm) of the main headers would impose GRP designs conditions at the edge of experience envelope.

Part of the evaluation of the design pressure was the performance of a surge analysis. The objective of the surge analysis is the verification of both the maximum and minimum pressure levels during steady state and upset conditions. The complete system was modeled and analyzed for the most severe upset condition.

Results

Surge analysis

- Introduction of a vacuum breaker at each pump connection was recommended in order to control the vacuum in the A/G GRP cooling water discharge header.

- A pipe pressure class of 10 barg would be fit for purpose for the U/G GRP cooling water pipe.

Stress analysis

- Rigid tensile resistant joints (laminations) were selected as the jointing system.

- Minimum required STIS 2100 Pa.

- Paralles pipe O.K. for top load of 100 KN/m2 if soil cover is 1500 mm or more.

- Settlement due to poor soil conditions was no problem for the headers stress wise.

- Flange loads at the GRP/Steel interface were acceptable if sufficient flexibility is introduced in the steel branch connections.