Pressure Surge Analysis

Introduction

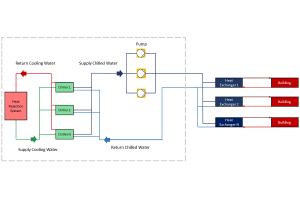

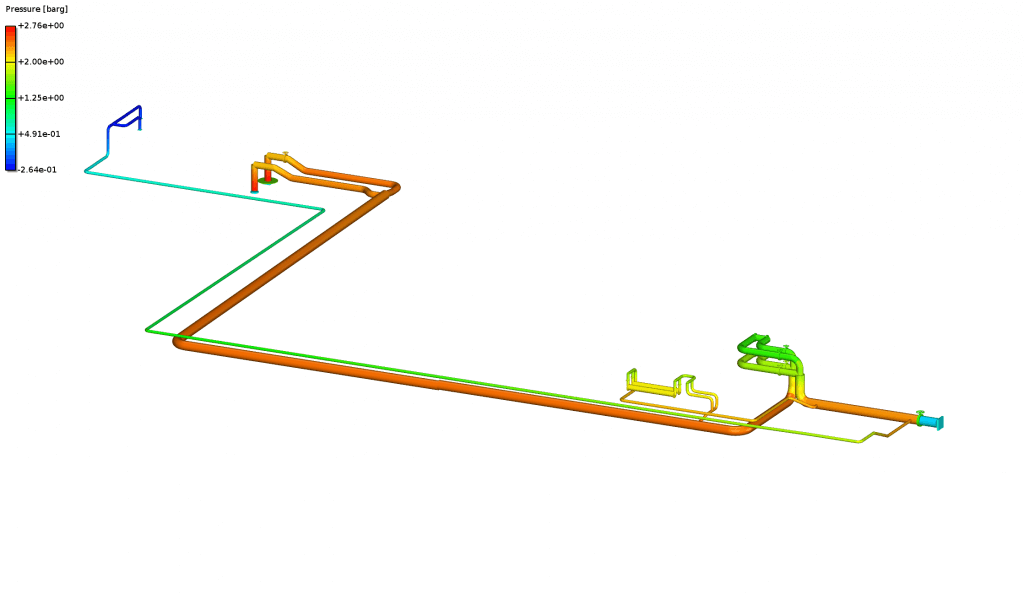

An existing power plant of Essent will be extended with a new power plant. The new power plant is based on a Combined Cycle Unit (CCU) which includes the combination of a Gas Turbine with a Steam System. The surface condenser of the new power plant is cooled by the main cooling water system, constructed out of fiberglass. A pressure surge analysis of the cooling water system was carried out using the software package BOSfluids.

Analysis

Based on the steady state condition six critical upset scenarios involving pump failures and pump start-up sequences were identified to be studied in the pressure surge analysis. The objectives of the pressure surge analysis were:

- To define the maximum and minimum pressures during the various upset scenarios, such as valve closure and pump trips.

- To define necessary measures to protect the cooling water network against overpressures or vacuum conditions that exceed the pipe and equipment allowable values.

- To supply pressure / flow time history plots at important locations in the system.

Results

In all scenarios, pressure waves are generated that travel throughout the system and cause alternating high to low-pressure regions to occur in the piping and the majority of equipment. The results of these analyses are as follows:

- The used valve closure time of 30 seconds is sufficiently slow to prevent large water hammers from occurring.

- The pump start-up scenarios proved to hold no issues for the system.

- All maximum pressures calculated were well below the allowable of 5 barg.

- Minimum pressures at or around full vacuum occurred at several places during several scenarios. The piping at these locations are vacuum resistant and thus this occurrence is already accommodated Most cavities arose around the surface, condenser and heat exchanger due to column separation during single pump operation.

- Sizable unbalanced forces were found in the system due to the presence of sudden pressure changes in the large diameter piping. A stress analysis of the system should take into account these forces.

Based on the above results it can be concluded that the system is fit for purpose so long as it can withstand the unbalanced forces discerned from the analysis.