The Ærfugl MEG (Monoethylene Glycol) injection skid, engineered by Hitec Products AS for deployment on the Skarv FPSO, is a critical system designed to inject MEG into subsea flowlines, thereby preventing hydrate formation. Following the comprehensive pulsation analysis, which established compliance with API 674 DA2 pulsation criteria through targeted mitigation measures, the project advanced to a detailed assessment of the mechanical dynamic response. This phase specifically addresses the risks of vibration-induced fatigue in the skid’s piping system, a common concern in reciprocating pump installations where pressure pulsations can excite mechanical resonances.

Background and Context

The pulsation analysis part of the project quantified the pressure fluctuations throughout the suction and discharge piping under realistic operating conditions. The study revealed that, prior to mitigation, pulsations at several harmonics exceeded API 674 DA2 allowables—particularly the 12th harmonic on both suction and discharge sides. These exceedances, if left unaddressed, posed a risk of fatigue and mechanical instability

The implementation of a staged orifice solution successfully suppressed these high-frequency pulsations, reducing both pressure amplitudes and associated unbalanced (shaking) forces within the skid to acceptable levels. However, the analysis also identified elevated unbalanced forces in external piping, underscoring the importance of system-wide acoustic and mechanical coordination.

With the pulsation control measures in place, the focus shifted to evaluating the actual dynamic mechanical response of the skid piping when subjected to the calculated shaking forces. This phase ensures that the system is not only compliant with pulsation criteria but also robust against vibration-induced mechanical failure over its operational life.

Methodology

Model Development

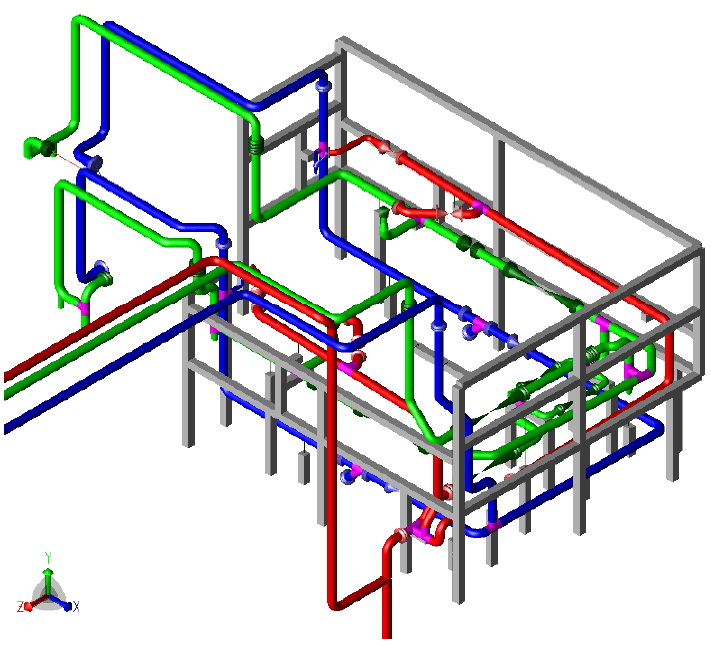

The dynamic stress assessment utilized a finite element model initially developed for the static pipe stress evaluation. This model was refined for dynamic analysis, incorporating the full extent of on-skid piping as well as relevant connected sections outside the skid to accurately represent boundary conditions.

Material properties, geometry, and support arrangements were sourced from as-built documentation and prior static studies, ensuring consistency and fidelity in the simulation.

Excitation Forces

The excitation (shaking) forces applied in the analysis were directly derived from the pulsation study results. These forces correspond to harmonics of the pump running speed, with the most significant amplitudes observed at the 3rd (19.5 Hz) and 6th (39 Hz) harmonics. For conservatism and to address model uncertainties, each set of shaking forces was applied across a ±10% frequency band around the nominal harmonic, enabling a frequency sweep to capture potential resonance effects.

The maximum shaking forces applied in the analysis were as follows:

- Pump 46-PB-005A: 14 N at 19.5 Hz, 61 N at 39 Hz

- Pump 46-PB-005B: 60 N at 19.5 Hz, 38 N at 39 Hz

These values represent the worst-case scenarios identified in the pulsation analysis and serve as the basis for assessing dynamic stress response.

Fatigue Assessment Criteria

Given the high-frequency nature of the excitation (and thus the high number of stress cycles over the system’s design life), the allowable stress amplitude was conservatively set at 45 MPa. This value corresponds to the fatigue limit for the piping material (UNS S31803 duplex stainless steel) at 10¹¹ cycles, as derived from ASME BPVC VIII-2 with an additional factor to account for welded joints. The primary objective was to confirm that all dynamic stress amplitudes remained well below this threshold, ensuring a robust margin against fatigue failure.

Results

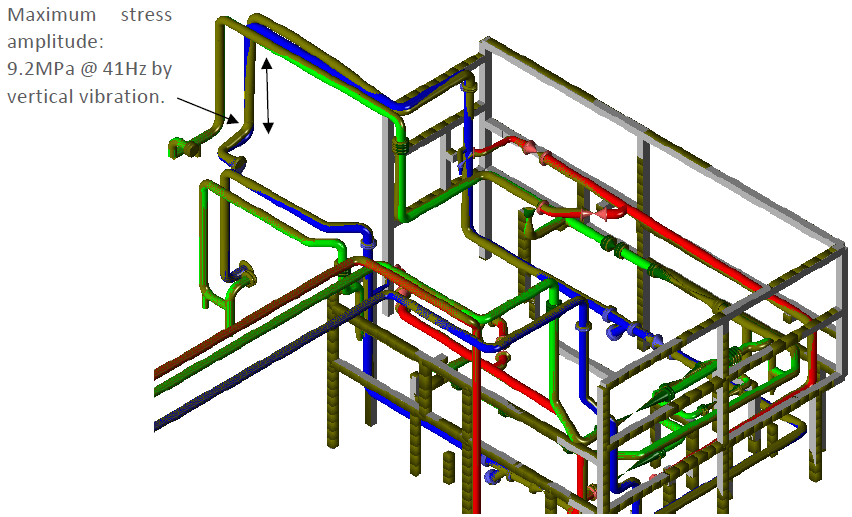

The dynamic analysis revealed that the maximum stress amplitude induced in the skid piping, under the worst-case excitation scenario, was 9.2 MPa. This peak occurred at a vibration mode near 41.2 Hz, which is close to the 6th harmonic of the pump frequency. The corresponding displacement amplitude at this mode was calculated as 0.15 mm (notably, this value is a scaled representation for visualization purposes).

Crucially, the observed maximum stress amplitude equates to only 20% of the allowable fatigue stress, providing a safety factor of 4.9. This substantial margin demonstrates that the combined effect of the implemented pulsation mitigation measures and the inherent mechanical robustness of the skid piping is sufficient to preclude fatigue failure under all anticipated operating conditions. No significant excitation of mechanical resonances was detected within the analyzed frequency range, affirming the resilience of the support arrangement and overall skid design.

The analysis also incorporated recent design changes, such as the addition of an extra PSV (Pressure Safety Valve) line. The impact of this modification on dynamic stress levels was found to be marginal, with no adverse effect on the overall integrity assessment.

Discussion

The successful suppression of pressure pulsations to within code limits, as achieved through the orifice-based mitigation strategy in the pulsation study, directly contributed to the favorable dynamic stress results observed in this study. The relatively low levels of induced shaking forces within the skid, when combined with a well-supported pipework system, minimized the risk of resonant amplification and associated fatigue damage.

A notable observation is the continued vulnerability of small-bore (cantilevered) branches to vibration-induced stresses. While the primary piping exhibited ample safety margin, these smaller branches are inherently more sensitive to dynamic excitation due to their reduced stiffness and mass. The study thus emphasizes the importance of proper bracing and support for these components, recommending that all small-bore branches be anchored back to the main header wherever dynamic loads are anticipated.

Additionally, while the internal skid piping demonstrated robust performance, the analysis reaffirmed the findings from Phase 2 regarding high unbalanced forces in external connected pipework. This highlights the necessity for ongoing coordination with adjacent system owners to ensure that external piping is similarly safeguarded against both acoustic and mechanical excitation.

Conclusions and Recommendations

The dynamic mechanical response analysis of the Ærfugl MEG injection skid confirms that, with the adopted pulsation mitigation measures, the system operates well within allowable stress limits for fatigue. The maximum calculated dynamic stress amplitude of 9.2 MPa represents only 20% of the conservative fatigue threshold for the skid’s piping material, ensuring an exceptional margin of safety for long-term operation. No design modifications are required based on the results of this study.

To consolidate the integrity and reliability of the MEG injection skid, the following actions are advised:

- Ensure all small-bore branches are adequately braced, in line with best practice for dynamic loading conditions.

- Conduct vibrational measurements during system commissioning to verify actual pulsation and vibration amplitudes align with analytical predictions, extending monitoring beyond the skid boundary as appropriate.

- Maintain active engagement with upstream and downstream system owners to address any residual risks associated with high unbalanced forces in external piping.

The integration of thorough pulsation control, robust mechanical design, and vigilant commissioning practices positions the Ærfugl MEG injection skid for sustained, trouble-free service in the demanding offshore environment of the Skarv FPSO.