Surge & Water Hammer Analysis In Pipelines

Surge and water hammer are critical challenges in fluid systems, often caused by sudden events such as valve operations, pump trips, or equipment failures. These events can disrupt steady-state fluid flow, leading to excessive surge pressures, increased pipe stress, and potential system damage.

At Dynaflow Research Group, we leverage our multidisciplinary expertise in both the dynamic aspects of fluid flow and the mechanical responses of piping systems to address these issues. Our comprehensive surge analysis services aim to assess and mitigate risks, ensuring the safe and efficient operation of your piping systems.

CHALLENGES WE SOLVE

Addressing Critical System Issues with Surge Analysis Services

- Large pressures: Can cause permanent deformation or rupture of pipelines

- Low pressures: Risk of pipeline collapse or leakage at joints and seals

- Reverse flow: Potential damage to pump seals and motors, and draining of storage tanks

- Pipeline movement: Overstress and failure of pipe supports and pipelines

- Low flow velocity: Can lead to the settlement of solids in slurry lines, causing blockages

- Large unbalanced loads: Vibration of mechanical structures, excessive loads on flanges and tank nozzles

- Cavitation: Occurrence can lead to problematic vibrations, unbalanced loads, and noise

PROTECTING PIPING SYSTEMS

Surge & Water Hammer Analysis for New and Existing Piping Systems

New Piping Systems

- Design Optimization: Identifying potential issues early for cost-effective design decisions

- Scenario Planning: Simulating multiple design scenarios for the safest configuration

- Equipment Sizing: Proper sizing of valves, pumps, and pressure suppression devices

- Regulatory Compliance: Ensuring designs meet safety standards from the outset

Existing Piping Systems

- Problem Diagnosis: Identifying root causes of issues like vibrations and leaks

- Retrofit Planning: Effective modifications or additions to mitigate surge problems

- Operational Optimization: Fine-tuning valve closures, pump operations, and control systems

- Risk Assessment: Evaluating system vulnerability and prioritizing upgrades

All Piping Systems

- Transient Scenario Modeling: Simulating critical events: valve closures and pump trips

- Pressure and Force Calculations: Determining maximum and minimum pressures and unbalanced forces

- Mitigation Strategies: Providing recommendations for surge prevention

- Fluid-Structure Interaction: Integrating with structural analysis tools to assess fluid-induced forces

- Compliance Verification: Ensuring systems meet industry standards and safety regulations

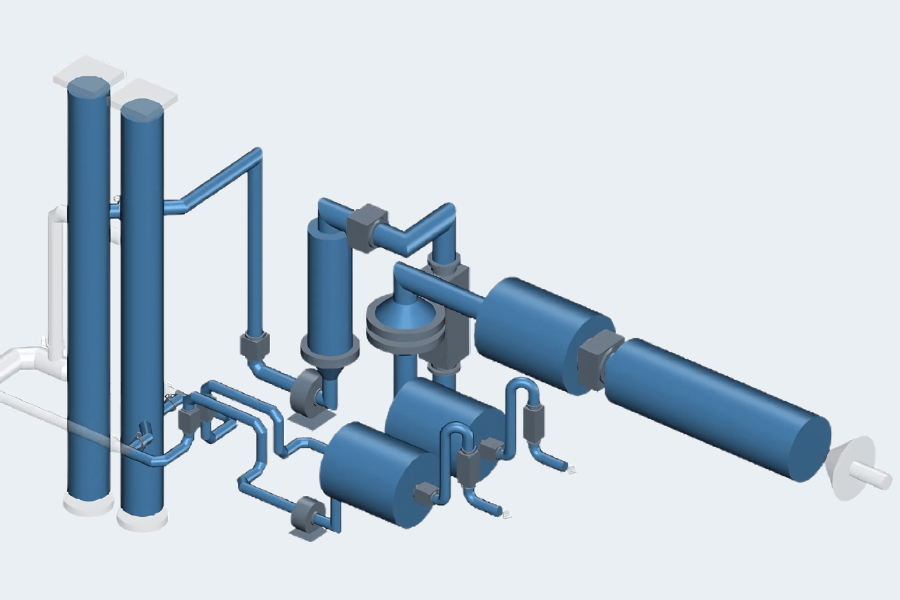

INDUSTRIAL PIPING SYSTEMS

Systems we Conduct Surge & Water Hammer Analysis For

- Piping systems

- Loading lines

- Pump and valve systems

- Fire protection systems

- Heat exchangers

- Storage tanks and reservoirs