Phone: +31 (0)85 058 0046

E-mail: infoaanvraag@dynaflow.com

E-mail: infoaanvraag@dynaflow.com

ABOUT US

HEAD OFFICE

Laan van Oversteen 20

6th floor

2289 CX Rijswijk

The Netherlands

Fitness for Service (FFS) is a critical aspect of engineering consulting, particularly in evaluating the structural integrity and safety of industrial equipment and components. Our engineering firm excels in providing specialized Fitness for Service assessments according to API 579 / ASME FFS-1.

Static equipment and piping are designed for a certain design life, often 25 years. During this prolonged use, the material may deteriorate, even when the system is used correctly, as a result of:

When the design life has been reached, the equipment may be re-assessed to determine its remaining service life, especially when the operating conditions effectuate creep, fatigue, or corrosion. When prolonged operation of the equipment is not possible, it is possible to de-rate the equipment.

During the design life, damage may also occur due to occasional events such as impact, overheating, severe wind (hurricane) loads, human errors such as forgetting to remove a temporary axial stop restraint, and more. Both the effects of prolonged use and occasional damages can be assessed by analysis conforming to the FFS code API 579.

DRG performs these types of assessments to conform to API 579 at all assessment levels. A level 1 assessment typically uses simple analytical criteria to pass/fail components. Level 2 assessments are similar to level 1, but the analytical criteria used to pass/fail components include the applicable damage in more detail. Both in level 1 and level 2 assessments, the damage must be located away from structural discontinuities. Level 3 assessment can be performed when level 1 and 2 assessments fail, or when the damage is close to or at structural discontinuities. With a level 3 assessment, damage in complex geometries subjected to general loading conditions is assessed using numerical analysis.

Dynaflow Research Group has extensive knowledge of API 579 and other codes referred to by API 579. We have decades of experience with mechanical and thermal analyses in FEA and piping analysis to compute piping and equipment nozzle loads. We also have extensive experience with the design and analysis of pressure vessels, boilers, heat exchangers, etc.

During these analyses, critical points in the system are identified. These critical points require priority when inspections, visual or using non-destructive testing (NDT) methods, are scheduled. Identifying these regions of increased concern in detail increases the likelihood of localizing material deterioration during inspection.

DRG has more than 35 years of experience with pressure vessels, boilers, heat exchangers, piping, etc.

Dynaflow possesses the skill, software and experience to perform any analysis conform API 579 / ASME FFS-1.

In addition to theoretical assessment, Dynaflow can be your partner for on-site inspections as well.

Local wall corrosion of piping and pipe fittings occurs over the system’s lifetime. The reduced wall thickness of the component can result in the system being deemed unsafe and unfit for service. In these scenarios the corroded component can be replaced, or an API-579 part 5 assessment can be performed. If the assessment is passed, the fitness for service of that component is confirmed and it is possible to extend its lifetime. If not, the component needs to be replaced, repaired, treated, or retired.

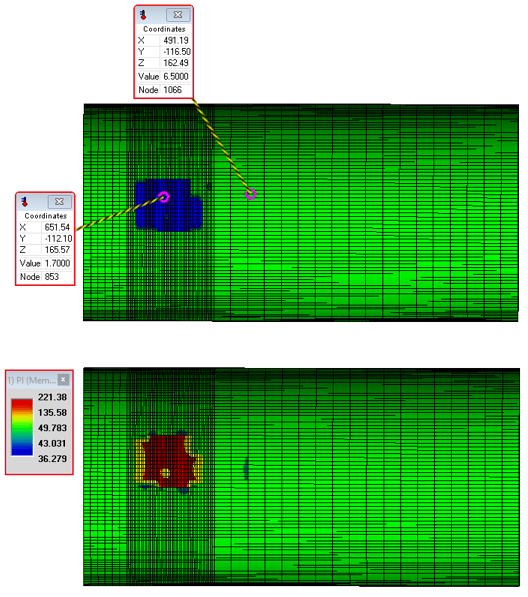

There are 3 assessment levels to an API-579 part 5 analysis. The level of assessment depends on the type of component and the proximity of the local metal loss to structural discontinuities. Each level increases the complexity of the calculation. Level 3 assessment requires finite element analysis. When the local metal loss is at a major structural discontinuity and supplemental loads are applicable, special consideration is required. The flexibility and plastic collapse capability are significantly affected as well as the stress distribution in that component.

Dynaflow Research Group regularly performs API-579, level 1, 2, and 3 assessments resulting in either extended service lifetime or a recommendation for component replacement.

In the case of local metal loss near a tee intersection an assessment according to API 579 part 5, level 3, is required. The tee with local metal loss is then explicitly modeled in FEA. With this approach, the altered stress distribution and stress levels are accurately captured. The remaining service life is then determined based on the corrosion rate of the component or using the MAWP approach. The thickness approach can only be used if the thickness of the component is characterized by a single thickness. When a thickness profile is required the MAWP approach must be used.

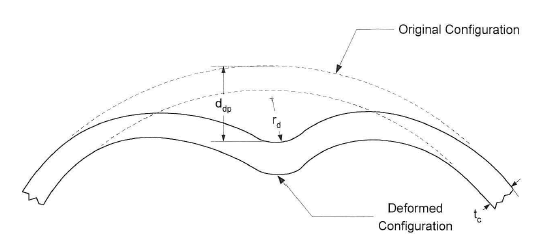

In older piping and equipment dents may be present. This may be caused for example by loading conditions or by accidents during maintenance or inspections. Dents in equipment may cause reduced allowable working pressure and may disqualify the component from its operation. This kind of damage may also raise uncertainty regarding the component’s toughness.

In those cases, an analysis conforming to API 579 part 12 can be used to quantify the damage and determine the component’s fitness for service. The location and size of the dent need to be determined. In the case of level 1 and 2 assessments, only the maximum depth of the dent is required. In a level 3 assessment, more detailed measurements are required to determine the dent profile in axial and circumferential directions.

When the dents are sufficiently far from Major Structural Discontinuities (MSD) and welds, a level 1 assessment of the dent is applicable. When the dent then satisfies the maximum depth criteria, no additional analyses are required. The next step is to verify that the MAWP, based on the thickness corrected with future corrosion allowance and past thickness loss, is equal to or larger than the original MAWP of the component. The assessment is then complete.

When the dents are far from MSD and welds, but are located in a region under cyclic loading, a level 2 assessment is applicable. In addition to criteria similar to level 1, the acceptable number of cycles is determined. This includes the past and future anticipated number of cycles.

When level 1 and 2 assessment criteria are not satisfied, a level 3 assessment can be performed. In a level 3 assessment, numerical analysis is required to verify that the component with the dent is fit for the applicable failure mechanisms, including plastic collapse, local failure, buckling, cyclic loading, or creep and creep fatigue.

DRG conducts piping flexibility assessments using the software Caesar II from Hexagon. Caesar II is used for both static and dynamic piping analyses. We have a thorough understanding of the software and are also an official Caesar II training provider for Hexagon. Caesar II is considered the industry standard for pipe stress analysis.

FEPipe is a template-based software solution specifically designed for use in the pressure vessel and piping (PVP) industry. Based on the chosen template, FEPipe performs detailed simulations using Finite Element Analysis (FEA) to comply with the ASME B&PV Section VIII Division 2. What separates FEPipe from general-purpose FEA software packages is its ability to rapidly construct PVP geometries and produce ASME code-compliant reports.

Abaqus is a robust general-purpose FEA software package. With Abaqus, it is possible to model and asses virtually any real-world problem for a wide range of industries. Abaqus has an extensive library with a wide range of element types and materials. It also allows the specification of custom materials. In addition to stress analysis, Abaqus can be used for convective and conductive heat transfer calculations, modal analyses, acoustics, and more.

Laan van Oversteen 20

6th floor

2289 CX Rijswijk

The Netherlands

© Dynaflow Research Group BV