ABOUT US

HEAD OFFICE

Laan van Oversteen 20

6th floor

2289 CX Rijswijk

The Netherlands

Firewater Systems are essential for any large building or industrial installation. A typical system contains wet and dry piping and may include a combination of sprinklers, hydrants, and monitors to provide water and foam to areas affected by a fire. Dynaflow has designed large-scale firewater and foam deluge systems certified by DNV. We are experienced with a range of international codes and standards. We base every design on the client’s Active Fire Philosophy and make sure it complies with the applicable codes and regulations such as DNVGL-OS-D301, NFPA, and ISO 13702. These code requirements form the basis for the firewater demand calculation and the subsequent firewater system layout design.

The firewater demand calculation is the starting point for the design of any firewater system. It gives a good indication of the flow requirements and the number of spray nozzles, hydrants, and monitors required to provide sufficient coverage on specific areas and equipment. The results of the demand calculation will form the basis for the detailed system design.

The result of the firewater demand calculation provides an estimate for the minimum required flow rate in specified areas. Sprinklers, hydrants, and monitors must be positioned so that the entire surface area is covered by their spray patterns. Depending on the layout and geometry of the areas to be covered, this may require more sprinklers than is strictly necessary to achieve the minimum flow rate. The sprinkler layout design provides the optimal nozzle types, spray angles, and positioning to ensure the safest and most efficient design. We can also provide recommendations to improve existing firewater systems when necessary.

DRG has more than 35 years of experience in solving surge problems that occur in deluge systems.

Our services comply with international and local firewater guidelines (NFPA, PGS28 among others) while providing detailed engineering services.

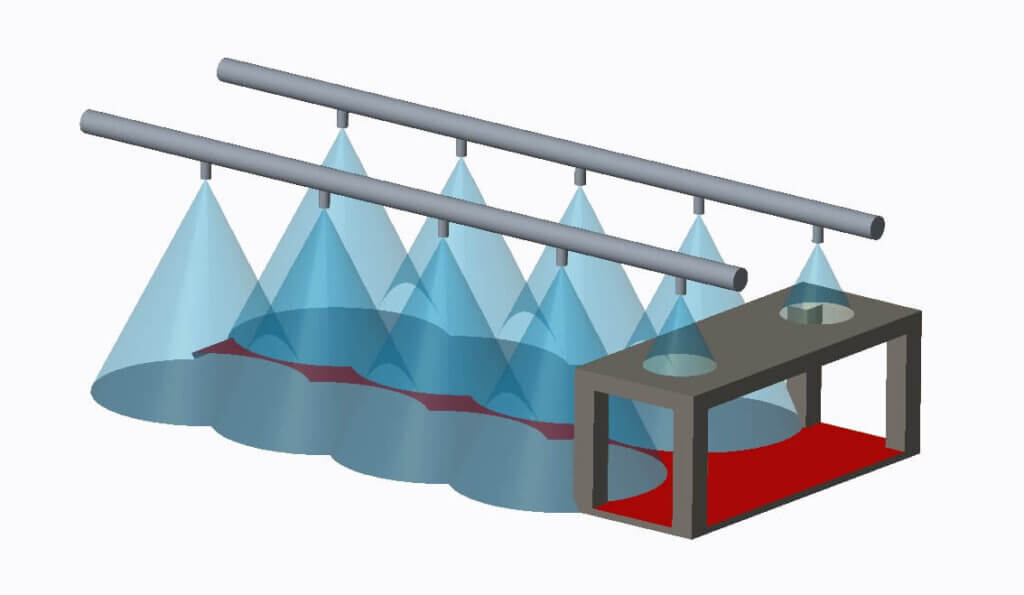

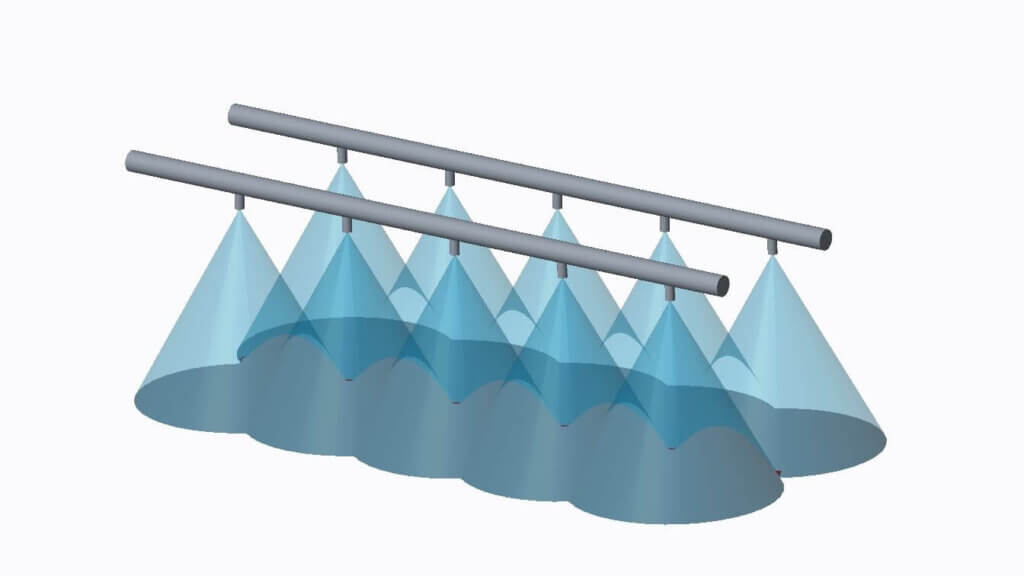

In firewater systems, it is important that the combination of sprinklers, hydrants, and monitors can cover the entire specified area.

In this example, the water from the sprinklers must fully cover the red area. Obstacles and spacing can be an issue with spray coverage. In this case, the sprinkler layout will need to be redesigned to fully cover the red area.

When the sprinklers are moved closer together and the obstacle is removed, the sprinklers can fully cover the red area. Alternatively, it might be required to add sprinklers underneath the obstacle. In this case, the sprinkler coverage is sufficient.

A firewater deluge system consists of an empty pipe network connected to sprinklers and/or monitors. A control valve separates the empty pipe system from a dedicated water supply. When firewater/foam is required, the control valve opens and water fills the empty pipes, activating sprinklers and monitors.

Filling of the initially dry system can result in high dynamic loads on the piping, as the waterfront moves through the system and changes momentum through each bend. When the waterfront finally reaches a sprinkler or monitor at the end of the line, the sudden flow restriction can cause pressure surges resulting in high unbalanced loads throughout the piping. DRG has more than 40 years of experience in solving surge problems, that often occur in deluge systems.

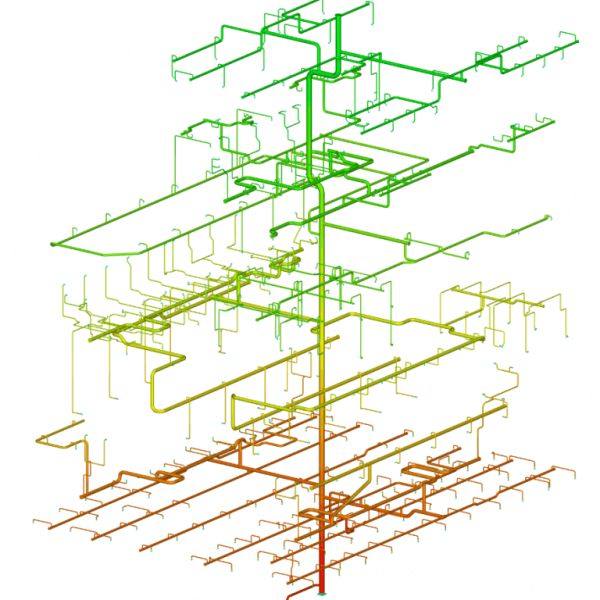

A hydraulic calculation may be performed to ensure that the piping can accommodate the water required at peak demand, and that sufficient flow reaches all areas of the system. A detailed 3D model of the piping, nozzles, hydrants, and monitors is then created, for which a steady state flow analysis is performed.

The hydraulic calculation gives a clear picture of the pressure distribution and flow rate throughout the system. Based on the results, we can provide recommendations regarding line sizing, nozzle selection, and potentially required changes to the system lay-out.

Our inhouse developed professional software solution BOSfluids is used to analyze the interaction between the fluid, the pipe and the structure.

Our inhouse developed professional software solution BOSfluids is an interactive and visual software package for the simulation and analysis of fluid flow to determine the flow rates, pressures and unbalanced forces in piping systems. It is an effective tool to study the steady state and transient flow conditions and help you perform coupled fluid-structure analyses.

Laan van Oversteen 20

6th floor

2289 CX Rijswijk

The Netherlands

© Dynaflow Research Group BV