Computational Fluid Dynamics For Industrial Applications

At Dynaflow Research Group, we specialize in addressing intricate flow problems that can hinder the optimal performance of pipelines and industrial equipment.

Our team of engineers possesses extensive computational fluid dynamics (CFD) expertise, enabling us to identify and resolve flow-related issues that may otherwise go unnoticed or disregarded.

CFD SERVICES

Capabilities of CFD Analysis in Solving Complex Flow Problems

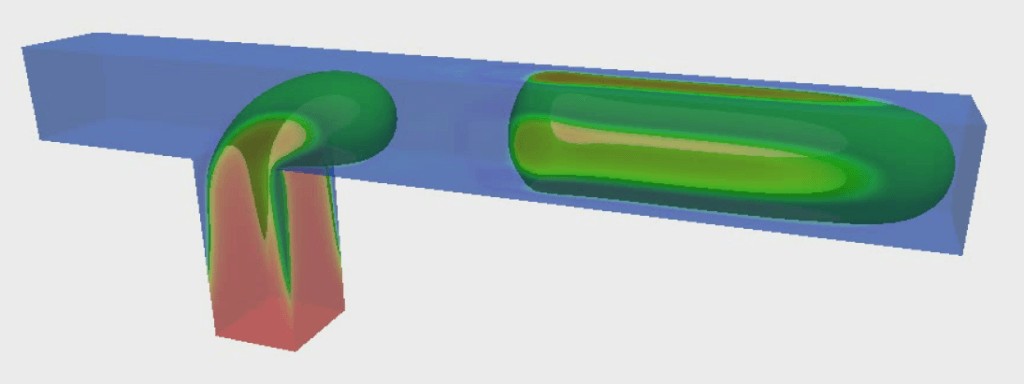

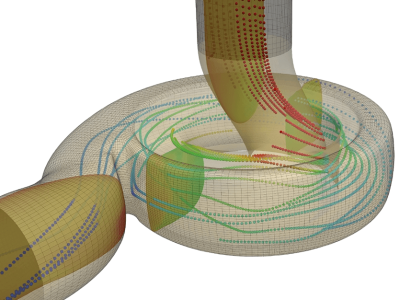

Computational Fluid Dynamics (CFD) is a sophisticated analytical tool that simulates and solves complex fluid flow and heat transfer problems in industrial equipment. By employing advanced numerical methods, CFD divides physical systems into smaller elements, enabling precise calculations of fluid properties such as velocity, pressure, and temperature.

At Dynaflow Research Group, CFD is applied to a range of industrial applications, including rotating machinery, heat exchangers, and pipelines. It helps engineers identify inefficiencies, optimize designs, and enhance equipment performance and safety. CFD analysis is particularly valuable for studying phenomena like pressure drops, flow separation, and thermal distribution in industrial systems.

The types of analyses that can be performed in a CFD application are:

- Optimizing design to improve performance

- Validating initial design performance

- Determining the cause of performance issues or failures

- Feasibility study of new configurations, e.g. closely spaced filters or pumps

- Fluid-structure interaction analysis to solve the interaction of some movable or deformable structure with an internal or surrounding fluid flow

CFD provides a detailed description of the complex flow patterns and properties in the system. Due to the flexibility of the analysis, CFD has a wide range of applications.

Moreover, due to recent advances in CFD, accurate predictions can be made about the flow properties of complex systems, such as pipeline components interferences, separation systems, or heat exchangers. This can be used to predict the performance of the analyzed system.

Furthermore, CFD models are easily revised and can offer many detailed insights into flow physics. Therefore, CFD can be used to replace expensive and time-consuming methods such as experiments, or for systems where no measurements are possible such as in deep sea applications or applications using liquid metal.

CFD APPLICATIONS

Expanding CFD Applications Across Diverse Industrial Systems

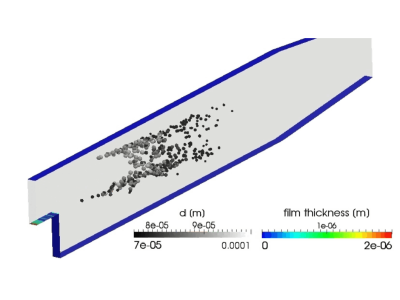

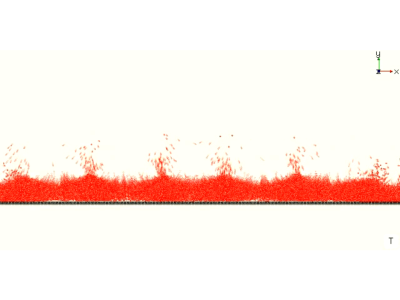

Multiphase Flow

Current 1D flow solvers struggle with capturing systems containing multiple phases due to their three-dimensional nature. CFD offers accurate insights into such fluid behaviors.

DRG has extensive experience in multiphase flow CFD analysis, covering various flow regimes, complex geometries, multiple scales, exotic non-Newtonian fluids, and dynamic geometries. We are confident in delivering precise results for any multiphase flow challenge.

Particle-Fluid Interaction

Structural Analysis in Equipment

In some cases, performing only a CFD analysis is not sufficient to approve the design of a system or to find the root cause of a failure. Structural analysis can also be an integral part of the analysis.

As Dynaflow Research Group is a multi-disciplinary engineering company, we can combine the results of a CFD analysis with a structural analysis.

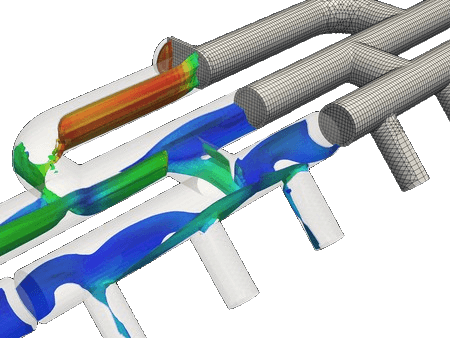

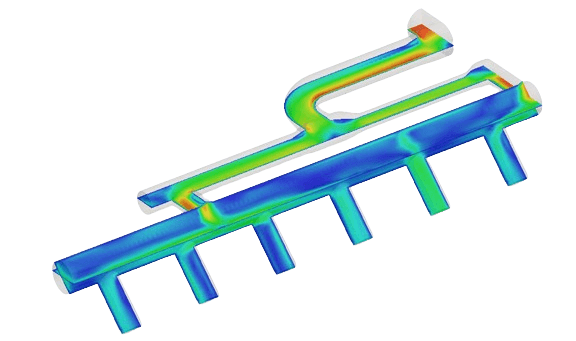

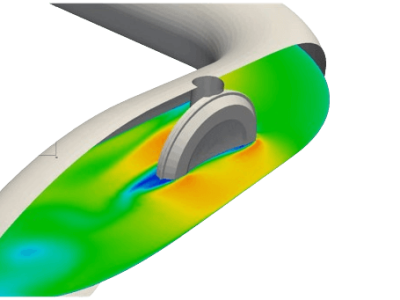

Optimization of In-Line Components

In-line components such as valves and orifices are key features of industrial installations. Using CFD the locations and design of these components can be optimized to mitigate possible failures or significant pressure drops due to hydrodynamic effects.

At Dynaflow Research Group we combine our extensive experience in working with these in-line components with parametric CFD models in order to optimize the design of your in-line components such as the following.

Other Applications

CFD analyses are not limited to the subjects discussed above. Many more applications are possible and are well represented in our project portfolio:

- Heat transfer in burners,

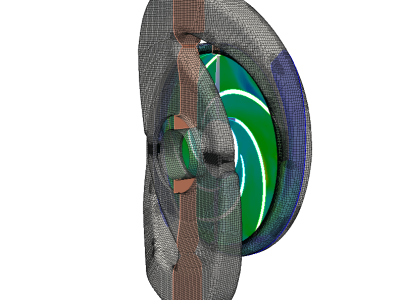

- Interference of pipeline components such as filters, valves pump inlet/outlet, etc.,

- Flow inside pumps and compressors.