Advanced Engineering Excellence Since 1989

Dynaflow Research Group excels in tackling complex engineering challenges related to flow, dynamics and fiberglass piping

WHAT WE DO

Specialized Solutions to Address Complex Engineering Challenges

DYNAMICS & FLUID FLOW

Specialized engineering services to optimize system performance and reliability:

- Flow: CFD, surge analysis, pulsation analysis

- Dynamics: Vibration analysis, RCA, fatigue assessment

FIBERGLASS ENGINEERING

Expert analysis and on-site maintenance services for fiberglass piping for new and existing systems.

- FRP Design & Engineering

- FRP Project Support

- FRP Commissioning Support

- FRP Research

SOFTWARE SOLUTIONS

State-of-the-art engineering tools for enhanced efficiency

- In-house developed solutions: BOSpulse, BOSfluids, ISOtrace, BOSview

- In-house software development team

TRAINING SOLUTIONS

Online and classroom training for a wide variety of courses in software, fiberglass engineering, and piping and pressure vessels.

SUCCESS STORIES

Delivering Impactful Engineering Solutions Across Multiple Disciplines

Assessment of potential internal explosion in H2-generation systems

Our client is a global company engaged in building end-to-end green hydrogen generation systems with a capacity between 1 and 10MW.

These units work through an electrolyzing process, confining in the same stack, oxygen and hydrogen at different compartments. Therefore, due to the existence of ignition sources, a potential risk of explosion is considered inherent to the system.

Given the extensive experience in complex dynamic assessment of piping and equipment, Dynaflow Research Group was tasked with finding a correlation between the data obtained from the explosion tests and simulations performed by the client and static pressure values that help prove compliance through static pressure tests.

Mitigating pressure surge impact in a process line at BASF Antwerp

The case study is focused on a surge analysis performed for a process line between two distillation columns at BASF Antwerp.

The process line considered here is in continuous operation, therefore it was deemed that rapid valve operation or unplanned pump rundown could give rise to the occurrence of pressure surges in this line.

The client wanted to assess the risk that these surges could pose to system safety and reliability

Surge analysis for firewater system for Green Hydrogen Facility

A new firewater (FW) system is being designed for a Green Hydrogen Elements facility. The plant spans a large area of approx. 2 x 1.5 km and contains multiple critical areas.

The piping material is Fiber Reinforced Plastic (FRP). The main firewater ring is of DN250 and DN300 piping. The piping material is supplied by Amiantit. The jetty lines are the only parts that are made of carbon steel.

The client has requested DRG to perform a surge analysis on the entire system to calculate minimum and maximum pressures and unbalanced loads.

Stress and surge analysis on the GRE seawater cooling piping for an ammonia plant

The client is operating multiple ammonia plants with similar cooling water systems made of GRE. Last year, failures were discovered in buried GRE components—specifically, an elbow and a tee—at one of the older plants.

A surge analysis conducted by Dynaflow Research Group revealed that these failures were due to an unfavorable piping layout at the failure location, leading to high pipe stresses.

Consequently, the client has engaged DRG to perform a static stress and surge analysis on a recently commissioned plant, even though it has not yet encountered any issues. This proactive approach aims to identify and mitigate potential stress-related failures in the GRE piping systems.

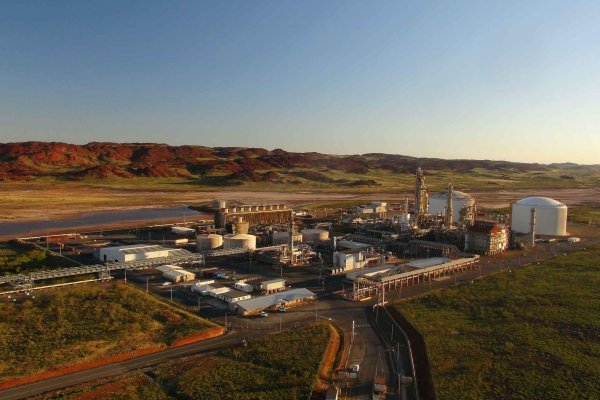

OUR CLIENTS

Leading Organizations Worldwide Rely on Our Expertise